Leman ferit, ke yo rele tou leman seramik, yo kreye lè l sèvi avèk teknoloji pwosesis seramik soti nan SrO oswa BaO ak Fe203. Leman sa a mande pou metòd machin espesyalize akòz dite ekstrèm li yo ak frajil, men li gen ekselan rezistans korozyon, yon ranje tanperati opere lajè, epi li pa chè. Leman pèmanan ki pi komen yo itilize jodi a se leman ferit, ki gen yon pakèt itilizasyon, tankou jwèt, atizana, ak loudspeakers ansanm ak motè ak lòt aparèy. Ti sèk ferrite leman pou atizana, pastan, ak piblisite.

Youn nan leman yo ak anpil aplikasyon aktyèl se leman ferit la. Akòz pri ki ba li yo, li se souvan itilize nan fou mikwo ond, moun kap pale, kas ekoutè, motè wotasyon, separasyon mayetik, motè DC, motè wotasyon, motè otomobil (eswiye, starter, ponp gaz, motè chèz, elatriye), ak lòt jaden. .

Avantaj:

Senp pwosesis fabrikasyon;

Trè bon estabilite tanperati;

Apwopriye pou itilize ant -40 ak 200 °C;

Stony ak frajil;

Idealman, evite korozyon;

Depi leman ferit sintered yo se oksid, yo pa pral rouye nan anviwònman difisil oswa yo pa pral afekte pa yon anpil nan pwodwi chimik (eksepte kèk asid fò), lajman itilize nan yon varyete aplikasyon pou, ki gen ladan sa yo ki enplike motè ak moun kap pale, epi li se cuttable ak zouti ki gen pwent dyaman.

Gen anpil leman disk seramik nan envantè nou an ki vini nan yon varyete gwosè; se pa tout yo parèt sou sit entènèt sa a. TchekeNeyodim disk lemansi ou bezwen yon leman trè pwisan.

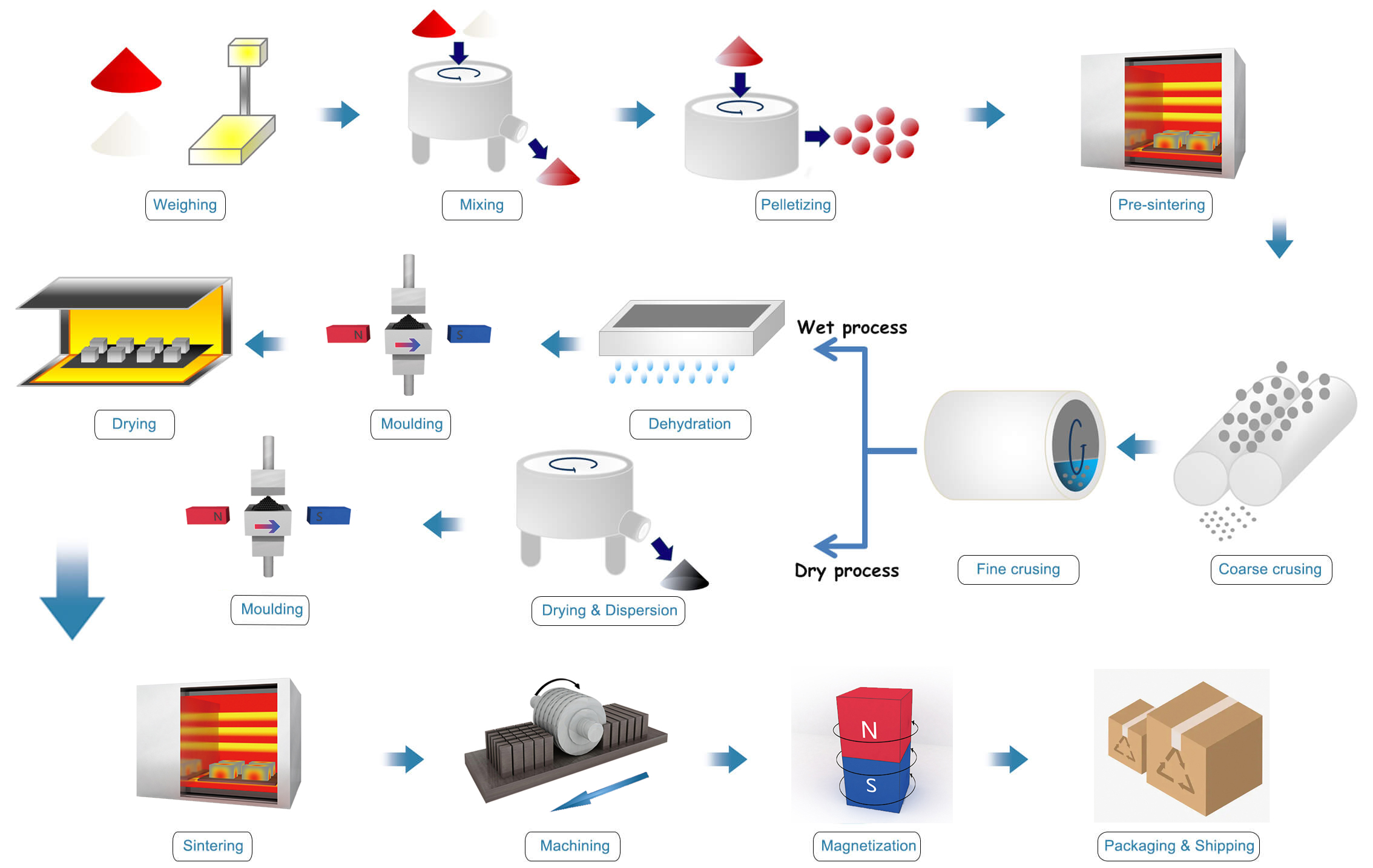

Pwosesis Faktori nan leman ferit

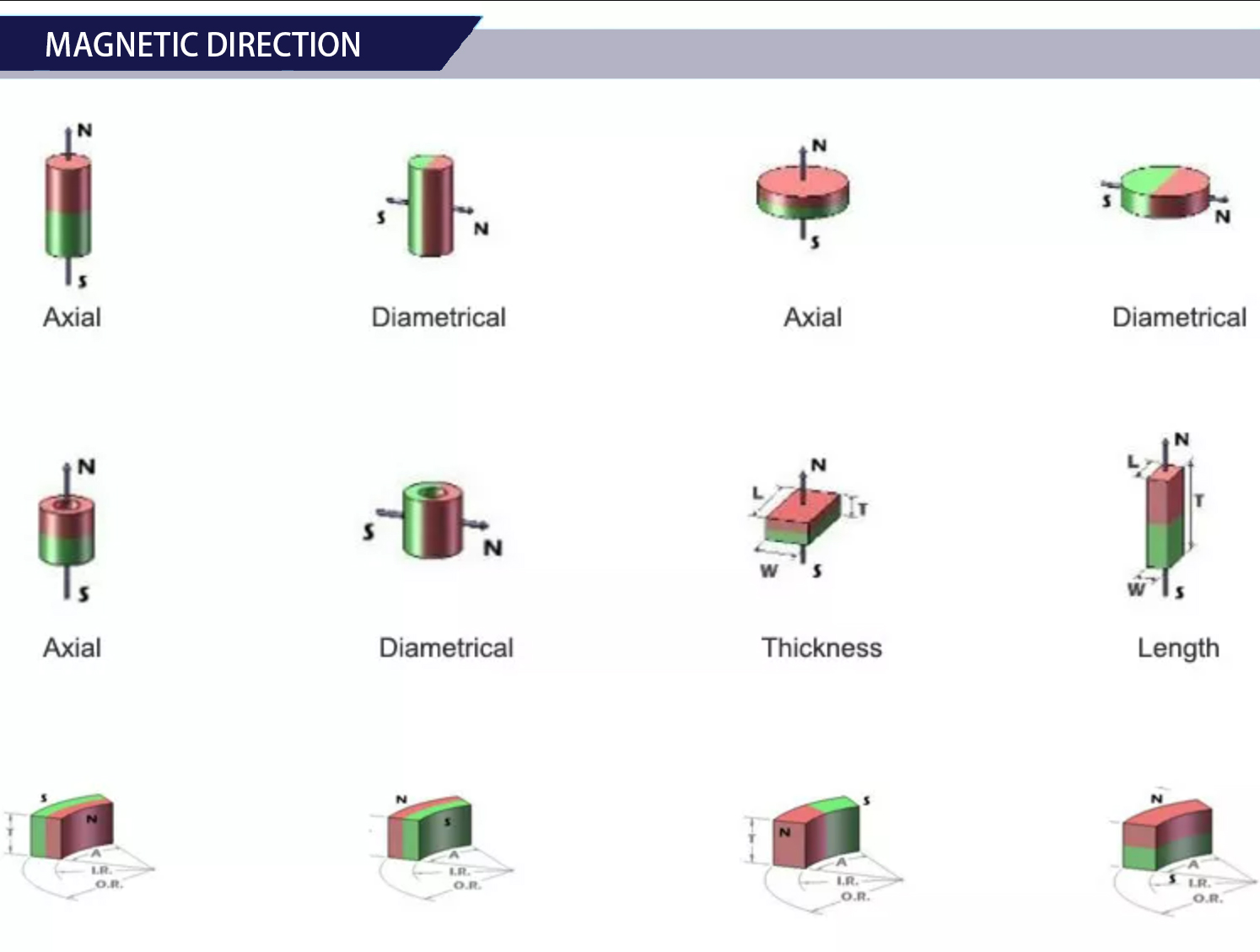

Direksyon mayetik

Pwopriyete mayetik

| Pwopriyete mayetik nan leman ferit | ||||||||

| Estanda Chinwa | ||||||||

| Klas | (Br) | (HcB) | (HcJ) | (BH) max | ||||

| mT | KGauss | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | |

| Y10T | 200-235 | 2.0-2.35 | 125-160 | 1.57-2.01 | 210-280 | 2.64-3.52 | 6.5-9.5 | 0.8-1.2 |

| Y20 | 320-380 | 3.2-3.8 | 135-190 | 1.70-2.38 | 140-195 | 1.76-2.45 | 18.0-22.0 | 2.3-2.8 |

| Y22H | 310 ~ 360 | 3.10 ~ 3.60 | 220-250 | 2.77-3.14 | 280-320 | 3.52-4.02 | 20.0-24.0 | 2.5-3.2 |

| Y23 | 320-370 | 3.2-3.7 | 170-190 | 2.14-2.38 | 190-230 | 2.39-2.89 | 20.0-25.5 | 2.5-3.2 |

| Y25 | 360 ~ 400 | 3.60 ~ 4.00 | 135-170 | 1.70-2.14 | 140-200 | 1.76-2.51 | 22.5-28.0 | 2.8-3.5 |

| Y26H | 360-290 | 3.6-3.9 | 220-250 | 2.77-3.14 | 225-255 | 2.83-3.21 | 23.0-28.0 | 2.9-3.5 |

| Y27H | 370-400 | 3.7-4.0 | 225-250 | 2.58-3.14 | 210-255 | 2.64-3.21 | 25.0-29.0 | 3.1-3.7 |

| Y30 | 370-400 | 3.7-4.0 | 175-210 | 2.2-2.64 | 180-220 | 2.26-2.77 | 26.0-30.0 | 3.3-3.8 |

| Y30BH | 380-390 | 3.8-3.9 | 223-235 | 2.80-2.95 | 231-245 | 2.9-3.08 | 27.0-30.0 | 3.4-3.7 |

| Y30-1 | 380-400 | 3.8-4.0 | 230-275 | 2.89-3.46 | 235-290 | 2.95-3.65 | 27.0-32.0 | 3.4-4.0 |

| Y20-2 | 395-415 | 3.95-4.15 | 275-300 | 3.46-3.77 | 310-335 | 3.90-4.21 | 28.5-32.5 | 3.5-4.0 |

| Y32 | 400-420 | 4.0-4.2 | 160-190 | 2.01-2.38 | 165-195 | 2.07-2.45 | 30.0-33.5 | 3.8-4.2 |

| Y33 | 410-430 | 4.1-4.3 | 220-250 | 2.77-3.14 | 225-255 | 2.83-3.21 | 31.5-35.0 | 4.0-4.4 |

| Y35 | 400-410 | 4.0-4.1 | 175-195 | 2.20-2.45 | 180-200 | 2.26-2.51 | 30.0-32.0 | 3.8-4.0 |

| USA Creole | ||||||||

| Klas | (Br) | (HcB) | (HcJ) | (BH) max | ||||

| mT | KGauss | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | |

| C1 | 230 | 2.3 | 148 | 1.86 | 258 | 3.5 | 8.36 | 1.05 |

| C5 | 380 | 3.8 | 191 | 2.4 | 199 | 2.5 | 27 | 3.4 |

| C7 | 340 | 3.4 | 258 | 3.23 | 318 | 4 | 21.9 | 2.75 |

| C8(=C8A) | 385 | 3.85 | 235 | 2.95 | 242 | 3.05 | 27.8 | 3.5 |

| C8B | 420 | 4.2 | 232 | 2.913 | 236 | 2.96 | 32.8 | 4.12 |

| C9 | 380 | 3.8 | 280 | 3.516 | 320 | 4.01 | 26.4 | 3.32 |

| C10 | 400 | 4 | 288 | 3.617 | 280 | 3.51 | 30.4 | 3.82 |

| C11 | 430 | 4.3 | 200 | 2.512 | 204 | 2.56 | 34.4 | 4.32 |

| Estanda Ewopeyen an | ||||||||

| Klas | (Br) | (HcB) | (HcJ) | (BH) max | ||||

| mT | KGauss | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | |

| HF8/22 | 200/220 | 2.00/2.20 | 125/140 | 1.57/1.76 | 220/230 | 2.76/2.89 | 6.5/6.8 | 0.8/1.1 |

| HF20/19 | 320/333 | 3.20/3.33 | 170/190 | 2.14/2.39 | 190/200 | 2.39/2.51 | 20.0/21.0 | 2.5/2.7 |

| HF20/28 | 310/325 | 3.10/3.25 | 220/230 | 2.76/2.89 | 280/290 | 3.52/3.64 | 20.0/21.0 | 2.5/2.7 |

| HF22/30 | 350/365 | 3.50/3.65 | 255/265 | 3.20/3.33 | 290/300 | 3.64/3.77 | 22.0/23.5 | 2.8/3.0 |

| HF24/16 | 350/365 | 3.50/3.65 | 155/175 | 1.95/2.20 | 160/180 | 2.01/2.26 | 24.0/25.5 | 3.0/3.2 |

| HF24/23 | 350/365 | 3.50/3.65 | 220/230 | 2.76/2.89 | 230/240 | 2.89/3.01 | 24.0/25.5 | 3.0/3.2 |

| HF24/35 | 360/370 | 3.60/3.70 | 260/270 | 3.27/3.39 | 350/360 | 4.40/4.52 | 24.0/25.5 | 3.0/3.2 |

| HF26/16 | 370/380 | 3.70/3.80 | 155/175 | 1.95/2.20 | 160/180 | 2.01/2.26 | 26.0/27.0 | 3.2/3.4 |

| HF26/18 | 370/380 | 3.70/3.80 | 175/190 | 2.20/2.39 | 180/190 | 2.26/2.39 | 26.0/27.0 | 3.2/3.4 |

| HF26/24 | 370/380 | 3.70/3.80 | 230/240 | 2.89/3.01 | 240/250 | 3.01/3.14 | 26.0/27.0 | 3.3/3.4 |

| HF26/26 | 370/380 | 3.70/3.80 | 230/240 | 2.89/3.01 | 260/270 | 3.27/3.39 | 26.0/27.0 | 3.3/3.4 |

| HF26/30 | 385/395 | 3.85/3.95 | 260/270 | 3.27/3.39 | 300/310 | 3.77/3.89 | 26.0/27.0 | 3.3/3.4 |

| HF28/26 | 385/395 | 3.85/3.95 | 250/265 | 3.14/3.33 | 260/275 | 3.27/3.45 | 28.0/30.0 | 3.5/3.8 |

| HF28/28 | 385/395 | 3.85/3.95 | 260/270 | 3.27/3.39 | 280/290 | 3.50/3.60 | 28.0/30.0 | 3.5/3.8 |

| HF30/26 | 395/405 | 3.95/4.05 | 250/260 | 3.14/3.33 | 260/270 | 3.27/3.39 | 30.0/31.5 | 3.8/3.9 |

| HF32/17 | 410/420 | 4.10/4.20 | 160/180 | 2.01/2.26 | 165/175 | 2.07/2.2 | 32.0/33.0 | 4.1/4.1 |

| HF32/22 | 410/420 | 4.10/4.20 | 215/225 | 2.70/2.83 | 220/230 | 2.76/2.89 | 32.0/33.0 | 4.1/4.1 |

| HF32/35 | 410/420 | 4.10/4.20 | 240/250 | 3.01/3.14 | 250/260 | 3.14/3.27 | 32.0/33.0 | 4.0/4.1 |

Aplikasyon

Poukisa Honsen Magnetics

Liy pwodiksyon konplè nou an garanti kapasite pwodiksyon soti nan matyè premyè rive nan pwodwi fini

Nou sèvi ONE-STOP-SOLUTION pou asire kliyan acha efikas ak pri-efikas.

Nou teste chak moso nan leman pou fè pou evite nenpòt pwoblèm kalite pou kliyan yo.

Nou ofri diferan kalite anbalaj pou kliyan kenbe pwodwi ak transpò an sekirite.

Nou travay ak gwo kliyan osi byen ke ti yo san MOQ.

Nou ofri tout kalite metòd peman pou fasilite abitid achte kliyan yo.